Motion Control Analysis

Modern motion control techniques, and linear motor technology have increased controllable

bandwidth to frequencies close to structural resonances. Our considerable experience measuring

and solving machine tool vibration allows you to get the most out of your motion control system,

whether you need increased gains for maximum bandwidth, or lower gains for improved resonant

damping.

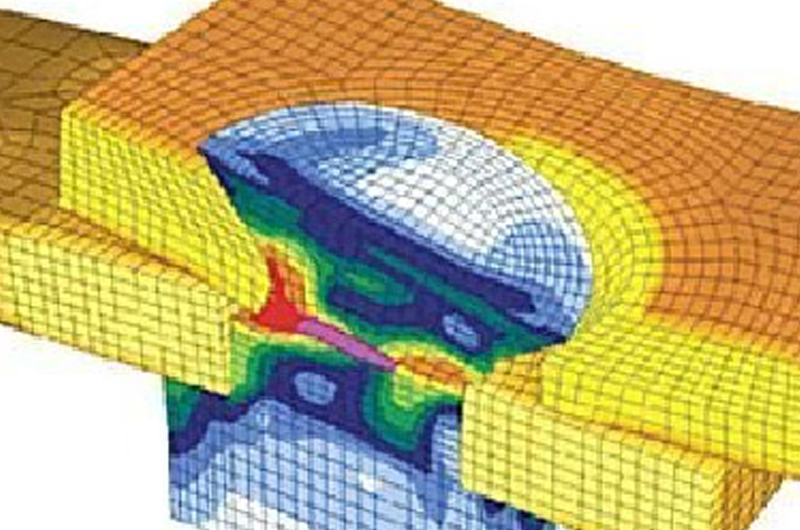

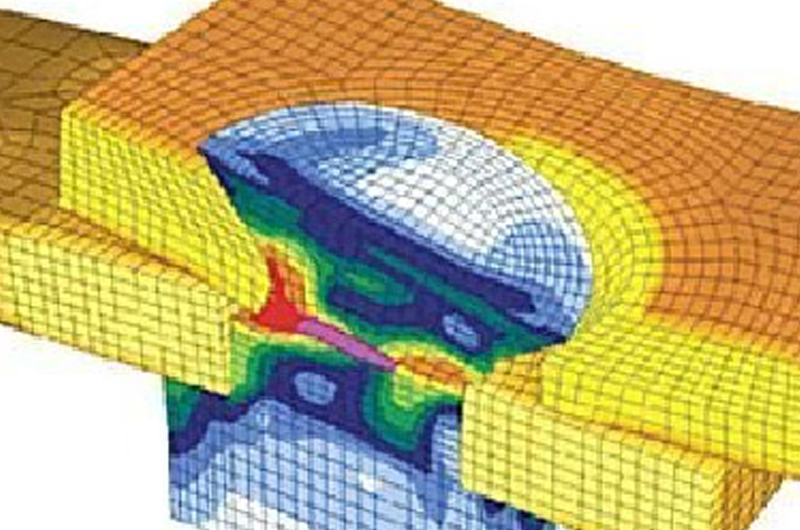

Vibration Analysis

FFT analyzers are used to measure the dynamic characteristics of structures. Our advanced testing

methods pin point the exact causes of vibration related problems. Our full line of

accelerometers, capacitance and velocity probes, impact hammers, electro-dynamic and hydraulic

exciters coupled with our computer based software allow us to measure vibration modes in

machinery and plot their mode shapes for a clear understanding of the problem. With this

knowledge a design modification can be implemented.

Advanced Damping Techniques

We possess the advanced technology of tuned damped vibration absorbers. These dampers allow us to

improve the damping characteristics of the structure in many cases many fold. In many cases this

is the most efficient way to improve the dynamic stiffness of the structure with sufficient

magnitude to completely solve the troublesome vibration problem. At the same time this may open

up new avenues of process improvement that were not possible previously.

Through detailed analysis of the machine structure it is often possible to improve the damping in

the structure through the use of squeeze film damping techniques. This method has been used

successfully many times and yields improvements at all frequencies.